Digital Twin

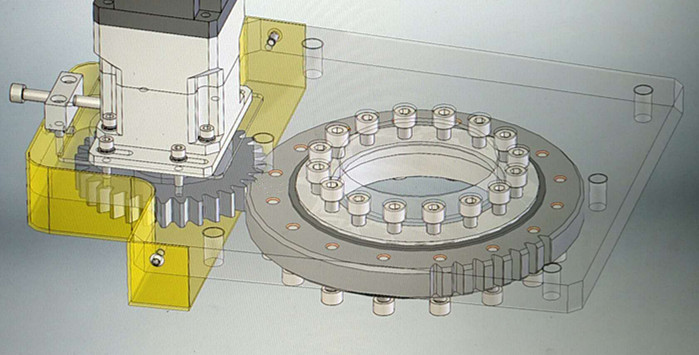

Simply put, "digital twin" is the combination of "virtual manufacturing" and "real production". For many industries, “paperless” and “digital prototypes” have been applyed in mechanical design. With the advancement of technology, the "virtual prototype" has become more and more functional and closer to the final "physical prototype". Therefore, people can head off problems before they emerge, reduce outages and costs, and even plan for the future by using simulations

BRS Bearing is also working on the virtual manufacturing, currently we can only provide CAD drawing of slewing ring products, and step file of limited models. With the help of bearing's 3D model, customer will be more convenient on bearing model selection.

Machine Learning and Artificial Intelligence Technology

This technology is predicted to become a ubiquitous part of life in the near future, it helps people to better collaborate with technologies.

As the development of AI, more and more robots will be in service, and each robots contains countless precision bearings, such as crossed roller bearing (RA/RB series) and angular contact ball bearings for their swiveling units. We believe this will be a giant market for bearing suppliers.

Autonomy and human-computer interaction

Human-computer interaction and collaboration is like our relationship with the smart phone in our hands. The mobile phone is more and more intelligent, and it will be more convenient for us to operate.